PORTFOLIO

My PROJECTS

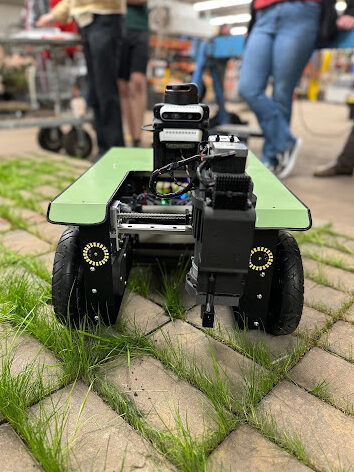

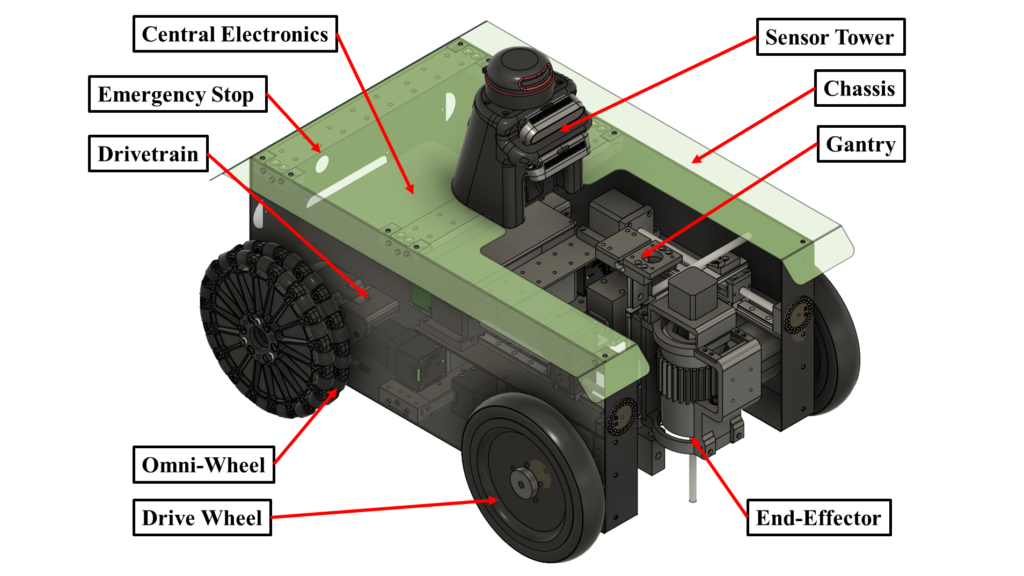

SWIPER: SideWalk Invasive Plant Eliminating Robot

Project Summary

I worked with a group of students to create a mobile robot to autonomously detect, navigate to, and uproot weeds on sidewalks to aid Northeastern’s Landscaping Department in handling weeds that grow around campus.

Design Steps

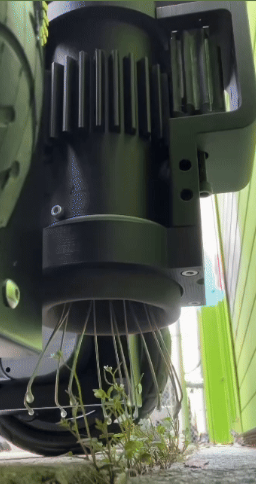

Conducted characterization testing to determine what factors were most important in order to successfully uproot weeds.

Prototyped various end effectors and compared their benefits and drawbacks.

Iterated on the design of a novel end effector concept which utilized a hyperboloid membrane to achieve firm yet compliant grip on weeds.

Integrated the end effector with the full system and conducted testing to further improve the design.

Challenges and Constraints

There were no existing autonomous systems which could uproot weeds from sidewalk cracks, so our approach could not be guided by current designs on the market.

We had to work alongside our client and ensure SWIPER could meet all of their needs in terms of safety, reliability, and time.

Ensuring that our autonomous robot was safe for use around pedestrians was a high priority and forced us to rethink our end effector design multiple times.

Results

SWIPER successfully uprooted weeds in 85% of test cases on both simulated and actual weeds. After presenting our SWIPER to a panel of judges, our team was awarded the Gorlov Prize for Innovation and placed first among all teams within the track. SWIPER will be handed off to Northeastern’s Robotics and Intelligent Vehicles Research Laboratory for further testing and research.

Heat Resistant Carafe SCale

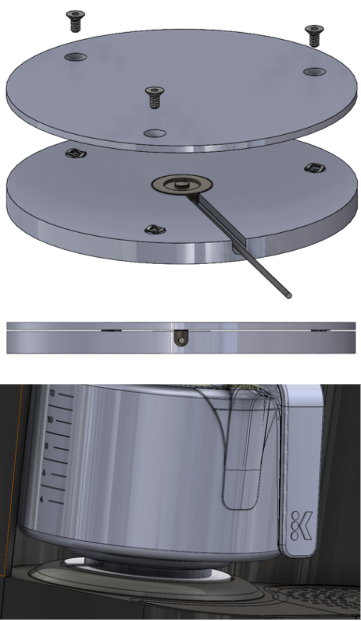

Project Summary

I conducted research and created a design for a heat-resistant scale in SolidWorks to measure the weight of a carafe during a coffee brew.

Design Steps

Researched methods of determining an object’s weight and generated concepts based on the methods I felt would be best suited for this application.

Utilized feedback from my peers as well as a decision matrix to choose which concept I wanted to move forward with.

Designed the load cell inclosure in SolidWorks, selected other necessary components, and created a bill of materials.

Learned how to correctly apply dimensions and tolerances to ensure the part was properly machined.

Contacted several vendors to find a load cell that fit my design criteria.

Challenges and Constraints

The design had to be versatile so that it could be used with both past and future generations of brewers.

Also, the design could not require any modifications to the brewer which meant I only had about a half inch of vertical space for my scale.

The group of brewers I was working with had a heating plate installed inside the base, so I had to work to mitigate the effects of the heating place so it would not impact the sensitive load cell.

Results

This design will significantly decrease the amount of time required for standard brewer testing by automating the process of data collection.

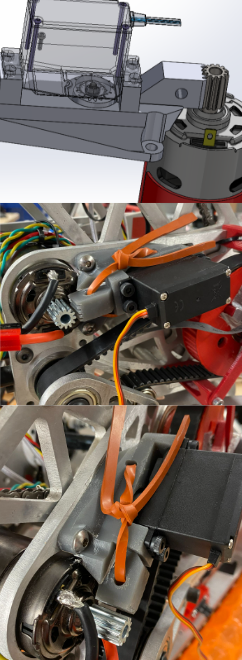

Robotic Arm Locking Mechanism

Project Summary

I designed and implemented a mechanism to secure the arm at a fixed position for when it is carrying an object across a long distance.

Design Steps

Researched various methods to lock an arm axis using solenoids, pneumatics, or motors.

Worked with the team to select the most practical method, which was to use a servo motor that could rotate a cam and push a rack into a pinion gear.

Designed the part in SolidWorks and made several revisions using feedback from peers.

Helped to assemble and test the locking mechanism and prove that it functioned as we intended.

Challenges and Constraints

There was very limited space for this part which required a more creative and uncommon design.

The rack had to be 3-D printed and revised several times in order to get the tolerances just right so that is moved smoothly.

The supports for the servo motor had to be designed so that they did not interfere with the cam and the rack.

Results

This new feature will prevent the motors from back-driving and improves the efficiency and precisness of the arm, while also reduces stress on the motors.

The pretty good coffee maker

Project Summary

I collaborated with a team of students to create a prototype for a new coffee maker that uses a customer’s feedback to modify certain brew parameters, like temperature and pressure, to make a better tasting cup of coffee.

Design Steps

Surveyed consumers in our market to gauge interest and determine critical features of our product.

Brainstormed what features we thought were both important to the coffee making process and feasible for us to accurately measure.

I Integrated a pressure sensor and a thermocouple into a common coffee brewing method to accurately measure the characteristics of each brew.

Challenges and Constraints

Our team had very little time and resources to complete this project, which caused us to have to work quickly and select only the most important design criteria to include in the prototype.

Results

We presented the concept along with our comprehensive business plan to a group of students and faculty, and ran a demonstration with our prototype

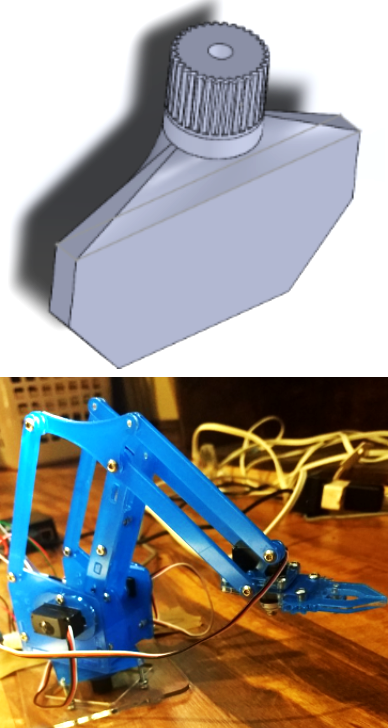

Say Hi tO Himap

Project Summary

I worked with a team of students to develope a prototype for a human-initiated mobile arm platform to provide a more efficient and safe replacement for human workers in warehouses.

Design Steps

Researched current industry solutions to the problem and confirmed that our prototype was truly unique and innovative.

Used SolidWorks to design housing for potentiometers and assembled the robotic arm.

Wrote a technical report explaining our process and discussing our findings.

Challenges and Constraints

This project was completed at the start of the Covid-19 pandemic, so our team had to navigate the transition from an in-person and very hands-on approach, to a more theoretical approach when we had to finish the project remotely.

Results

We presented the prototype and our findings to a group of students and faculty, and demonstrated the prototype’s capabilities.